Spectro Fluidscan Q1000 or The FluidScan® 1000 series handheld Infrared oil analyzer provides direct quantitative measurement of a lubricant’s condition and plays an important role in Machine Condition Monitoring (MCM) for proactive and predictive maintenance in Reliability Management programs. It determines when oil needs to be serviced due to degradation of the oil chemistry or contamination by other fluids such as water or the wrong oil. It is compliant with ASTM D7889 “Standard Test Method for Field Determination of In-Service Fluid Properties Using IR Spectroscopy”.

It also fulfils the National Emission Standards for Hazardous Air Pollutants for Reciprocating Internal Combustion Engines (NESHAP RICE) requirements for extending oil change intervals in engines and back-up generators when used in conjunction with the Spectro Q3050 Portable Viscometer.

Operating Principle

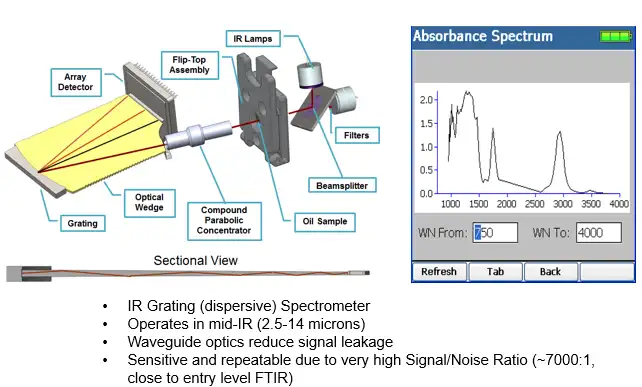

The FluidScan® is a self-contained handheld InfraRed analyzer that delivers instant fluid condition assessment to the user. It eliminates sample preparation and time-consuming cleanup using a patented flip top sampling cell for easy and rapid on-site analysis. At the core of the FluidScan is a patented, mid-infrared spectrometer with no moving parts. The spectrometer collects the infrared light transmitted through the fluid in the flip top cell into a waveguide. The waveguide then carries the light to a prism-like diffraction grating that reflects the light into a high-performance array detector which registers the infrared spectrum of the fluid. It provides more than adequate spectral range, resolution and signal-to-noise ratio for the rapid analysis of in-service lubricants.

Within one minute of sample introduction an InfraRed absorption spectrum of the fluid under test is produced by the Fluidscan optical system, and different calibration algorithms are then applied to the spectrum from a stored library of about 700 different fluids to produce parameters such as Oxidation, Total Base Number, Total Acid Number, depending on the fluid type. Spectro Scientific patented total water algorithm based on InfraRed Spectroscopy enables free water and dissolved water measurement to 300ppm for turbine oils. Parameter specific alarm limits stored in the Fluidscan device are applied to resulting parameters so user can immediately view pass/fail information on the device display.

| Oil Type | Properties Measured by FluidScan |

| Transmission | Water (PPM), Oxidation (Abs/0.1mm) |

| Hydraulic – Fire resistant (Phosphate Ester) | Water (PPM), TAN (mg KOH/g) |

| Hydraulic – Aerospace (Synthetic Hydraulic Fluid) | Water (PPM), Oxidation (Abs/0.1 mm), Alien Fluid mineral based (MIL-H-2304) (%), and Alien Fluid engine oil (ML-H-23699) (%) |

| Heat Transfer (Quenching Oil) | Water (PPM), Oxidation (Abs/0.1 mm) |

| Industrial (Steam and CCGT Turbine, Hydraulic, compressor, Chiller, Gear, etc.) | Water (PPM), Oxidation (Abs/0.1 mm), TAN (mg KOH/g) |

| Turbine Aerospace (Synthetic Gas Turbine Oil) | Water (PPM), TAN (mg KOH/g), Antioxidant (% depletion) |

| Engines (Engine oil for different engine types, including Gasoline, Diesel, Heavy Duty Diesel, HFO, Natural Gas, ctc) | Water (PPM), Oxidation (Abs/0.1 mm), TBN (mg KOH/g), Sulfation (Abs/0.1 mm), Nitration (Abs/cm), Soot (%), Glycol (%), Anti Wear (%) |

| Ethanol in Gasoline | Ethanol (%) |

| FAME in Diesel | FAME (%) |

| Biodiesel Feedstock | Water (PPM), FFA % |

| Biodiesel | Water (PPM), TAN (mg KOH/g), Total Glycerin (%) |

ASTM Compliance

- ASTM D7889 Compliant – “Standard Test Method for Field Determination of In-service Fluid Properties

Easy to use

- Needs just one drop of oil and one minute to test

- No solvents required to clean

- Color coded alarm levels

Fluid Manager desktop application provides:

- Report capability

- Device synchronization

- Data backup

- Asset Manager database

Multivariate Calibration

The FluidScan classifies fluids into groups called families based on their chemical makeup, usage and spectral signature. Family-specific algorithms are assigned that accurately quantify these amounts. The TAN, TBN and water are calibrated directly to wet chemistry titration readings. Soot is calibrated to soot percentages determined by thermo-gravimetric analysis. Glycol and incorrect fluid percentages are calibrated to samples prepared with known concentrations of glycol and incompatible fluids. The table summarizes key FluidScan properties and the ASTM protocols to which they correlate as a result of this calibration process.

| Item | Fluidscan Method (Correlation) |

| AW Additives | ASTM D7412/E2412 (FTIR) |

| Oxidation | ASTM D7414/E2412 (FTIR) |

| Sulfation | ASTM D7415/E2412 (FTIR) |

| Nitration | ASTM D7624 (FTIR) |

| Glycol | ASTM E1655 and E2412 |

| Soot | ASTM D5967 (Thermo-Gravimetric Analysis) |

| TBN | ASTM D4739 (Titration) |

| TAN | ASTM D664 (Titration) |

| Water | ASTM D6304 (Karl Fischer Titration) |

Applications library

The 700 oils in Fluidscan database are classified by oil type and then grouped together for different applications. The table below specifies the part number for library license, intended application, and types of oils included in the library. Library license is specified at the time of FluidScan purchase and can be upgraded later.

| PN | LIBRARY | OIL CATEGORIES INCLUDED |

| FL364 | Automotive | Engine, Engine-Natural Gas, Hydraulic, Transmission |

| FL365 | Aviation | Compressor, Engine, Hydraulic, Hydraulic – Fire resistant, Hydraulic-Aero, Turbin-Aero |

| FL366 | Fuel QC | Biodiesel, Biodiesel Feedstock, Ethanol in Gasoline, FAME in Diesel |

| FL367 | Industrial | Chiller, Compressor, Engine, Engine-Heavy Duty, Engine-Natural Gas, Gear-Pressure, Gear-Splash, Heat Transfer, Hydraulic, Hydraulic-Fire Resistant, Slideway, Transmission, Turbine-Aero, Turbine-CCGT, Turbine-Steam |

| FL368 | Lab Trend | ASTM Petroleum Engine, ASTM Polyol Ester (Turbine) |

| FL369 | Marine | Chiller, Compressor, Engine, Engine-Heavy Duty, Engine-HFO, Gear-Pressure, Gear-Splash, Hydraulic, Transmission, Turbine-CCGT, Turbine-Steam |

| FL370 | Military | Chiller, Compressor, Engine, Engine-Heavy Duty, Engine-HFO, Gear-Pressure, Gear-Splash, Hydraulic-Fire Resistant, Hydraulic-Aero, Turbine-Aero |

| FL371 | Railroad | Railroad Compressor, Engine, Engine-Natural Gas, Hydraulic, Transmission |

| FL360 | All Libraries | All Categories of oils included |

Product Models

| PN |

FluidScan 1000 |

FluidScan 1100 FluidScan 1100 |

| Color | Yellow | Blue |

| Default library | None. One free library from FL364 to FL371 at time of purchase | Industrial |

| Upgradable to full library | Yes | Yes |

| Total water license | Optional | Optional |

| Route base analysis | No | Yes |

| OilView Interface | No | Yes |

| Intended application | Fleet, marine, military, aerospace, fuel QC | Industrial manufacturing plants, power plants |