AMETEK Spectro

Scientific’s on-site oil

analysis tools have enabled

Honda Performance

Development to support

WTR Andretti and Meyer

Shanks ARX-06 race cars

to the podium.

Introduction

Honda Performance Development (HPD) faced a formidable

challenge during the Rolex 24-hour endurance race in

January 2023.

Their most advanced ARX-06 GTP (Grand Touring Prototype)

race cars, which would be racing competitively for the first time

with new engine hybrid technology, and a new IMSA-approved

renewable fuel.

Given the multitude of variables, HPD anticipated the emergence

of new wear trends attributable to the hybrid design. Employing

onsite oil analysis of both engine oil and transmission fluids

stands as one of the numerous methods for predicting failures.

HPD deployed its trackside oil analysis lab and support team to

Daytona, providing consistent onsite testing and analysis for WTR

Racing and Meyer Shank Racing cars throughout the 24-hour race.

This case study explores how HPD effectively managed and

resolved these challenges, showcasing their engineering prowess

and commitment to performance excellence.

Background

Mating a 671hp (500kW) 2.4L twin turbocharged V6 engine to

a Bosch hybrid battery drive and new transmission meant that

engine and gearbox wear needed to be constantly monitored

throughout the race.

A new racing fuel with a high ethanol content can also lead to

unexpected issues, primarily excessive fuel dilution, which, if left

unchecked, would result in viscosity loss, leading to premature

cylinder and crankcase wear. With engines pushed to the redline

during the race, accelerated failure due to wear can occur in

minutes. Replacing engines midway through the race, if required,

jeopardises the driver and team standings. Onsite oil analysis

tools provide the extra data for the trackside engineers to compile

into their Race plan.

The first sign of trouble emerged during the practice sessions,

when HPD’s technical team noticed irregularities in fuel analysis

and abnormal engine wear patterns. Upon further investigation,

it was revealed that the race cars were experiencing

higher-than-normal levels of fuel dilution in the engine oil,

affecting overall performance and reliability.

Onsite oil analysis fortrackside support

- Be robust, avoiding the need for solvents and gases

- Be high performance, accurate and fast

- Detect ferrous and nonferrous wear by element for signs of problems

- Monitor physical parameters as needed to support why wear is occurring

Figure 2. SpectrOil 120C.

Solutions

HPD developed an innovative approach to monitor the extreme conditions of a 24-hour duration race.

A SpectrOil 120C was the choice for trackside support teams because of its consistency, ease of use,

and fast response on a 2 ml sample. Sub-ppm results for wear metals, additives, and contaminants are

uploaded to the engineering race management systems as soon as results are generated, providing

excellent predictive data related to engine performance.

New trackside testing and validation

The next generation solution – FieldLab 58C was also introduced to the trackside.

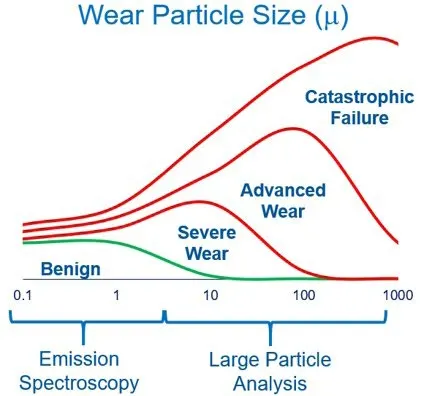

One of the core features of the device is the capability to measure all the severe (>4 micron) wear

particles by elemental analysis. These wear particles serve as early indicators of abnormalities in

engines and gearboxes.

FieldLab 58C also has the capability to look at the chemistry and viscosity, which is not only a

great indicator for fuel dilution, but also the integrity of the lubricants.

Figure 3. FieldLab 58C.

- Rugged and robust design

- No need of solvents

- Storability

- Onboard diagnostics for actions taken right away

- Abnormal abrasion, adhesion & fatigue wear particles are large, including base metals, not just surface oxides.

- Microspall particles renge between 10 μm and 50 μm.

- Laminar particles and chunks range from 50 μm to several hundreds of microns. Optical emission spectroscopy is blind to large particles.

Figure 4. The new elements module on FieldLab 58C is detects abnormal wear earlier than other oil analysis techniques